TBC

TBC

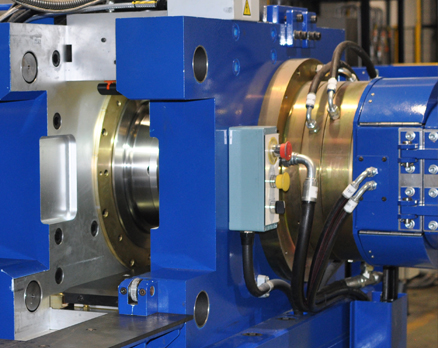

Continuous Rotary Extrusion machines are designed to last for many years, and Holton Crest design each machine around the individual process needs of each customer to maximise production value, but each component part has a natural lifecycle and will periodically need to be replaced. Many of these spares are available ‘off the shelf’, but Holton Crest also manufacture a wide range of parts to individual customer specifications. To ensure that optimum production can continue with minimal down time it is important to carry a stock of the most common spare parts for quick replacement.

It is important for any manufacturer to maintain optimum production levels at all times, and any machine down time costs money. However, due to the industrial nature of Continuous Rotary Extrusion, there is often a requirement to clean and repair certain elements of the machinery, which could take up to 24-48 hours to complete.

Therefore, Holton Crest have specifically designed a number of parts and assemblies within the machines to be quickly and easily swapped for a duplicate part so that production can continue whilst the original part is being cleaned or repaired. These assemblies are quick and easy to set up and not only enable continuous production, but also extend their lifecycle before new parts are needed.

With the Continuous Rotary Extrusion process, there are a number of moving parts that come under significant heat and pressure, which inevitably leads to wear and tear. Depending upon the level of production, some of these parts can wear out and need replacing every day, such as abutments for example. Other parts such as feed plates or tooling clamps will last longer, but will still require replacing at regular intervals, so it is important to maintain a regular stock of necessary consumable items to ensure that production can continue without interruption when these items need replacing.